Technology

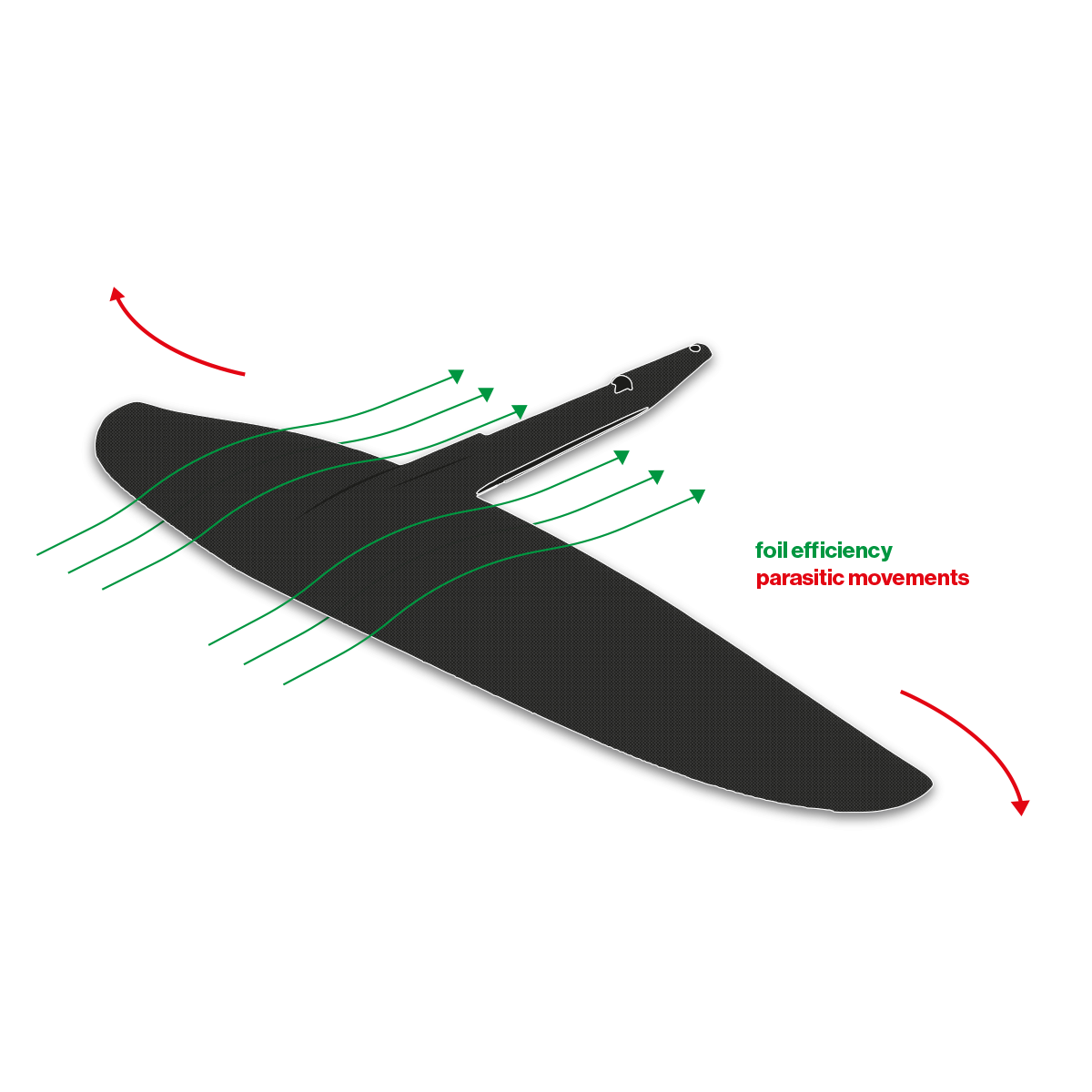

MONOBLOC STRUCTURE

Having a stiff and solid assembly between all the parts of the foil is key to making it perform at its best as well as easy to handle.

The connection of the front wing with the fuselage is highly stressed and loaded, so it is one of the critical areas of the assembly in terms of structures.

The Monobloc wings are molded together with the fuselage in one shot, thereby removing the connection and the chances for unwanted and parasitic movements.

The structural fibers of the fuselage are spread into the wing to achieve the smoothest and lightest connection.

It is also incredibly stiff and provides absolute control at all times, with the foil responding perfectly to all of the riders’ input.

When the overall dimensions are too large for convenient transportation, a connection is set into the fuselage, behind the mast where the loads are smaller.

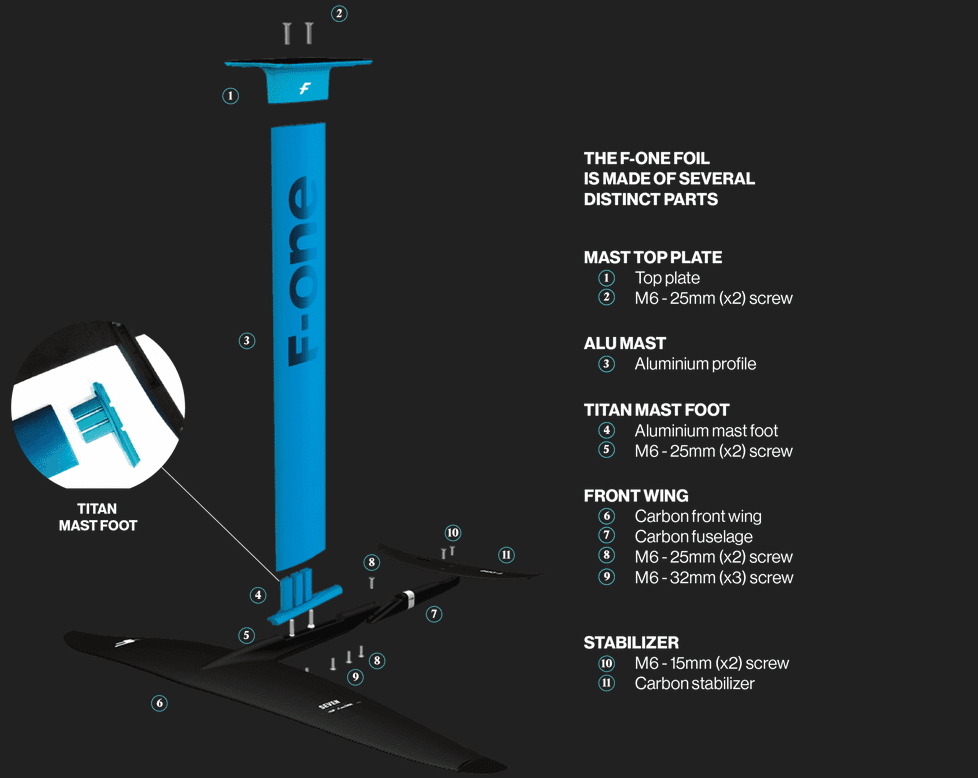

TITAN CONNECTION

The TITAN connection enables a very stiff and direct connection between two parts, locking efficiently any movement in all directions.

Its format is compact which is hydrodynamically efficient and very easy to use, assemble and disassemble.

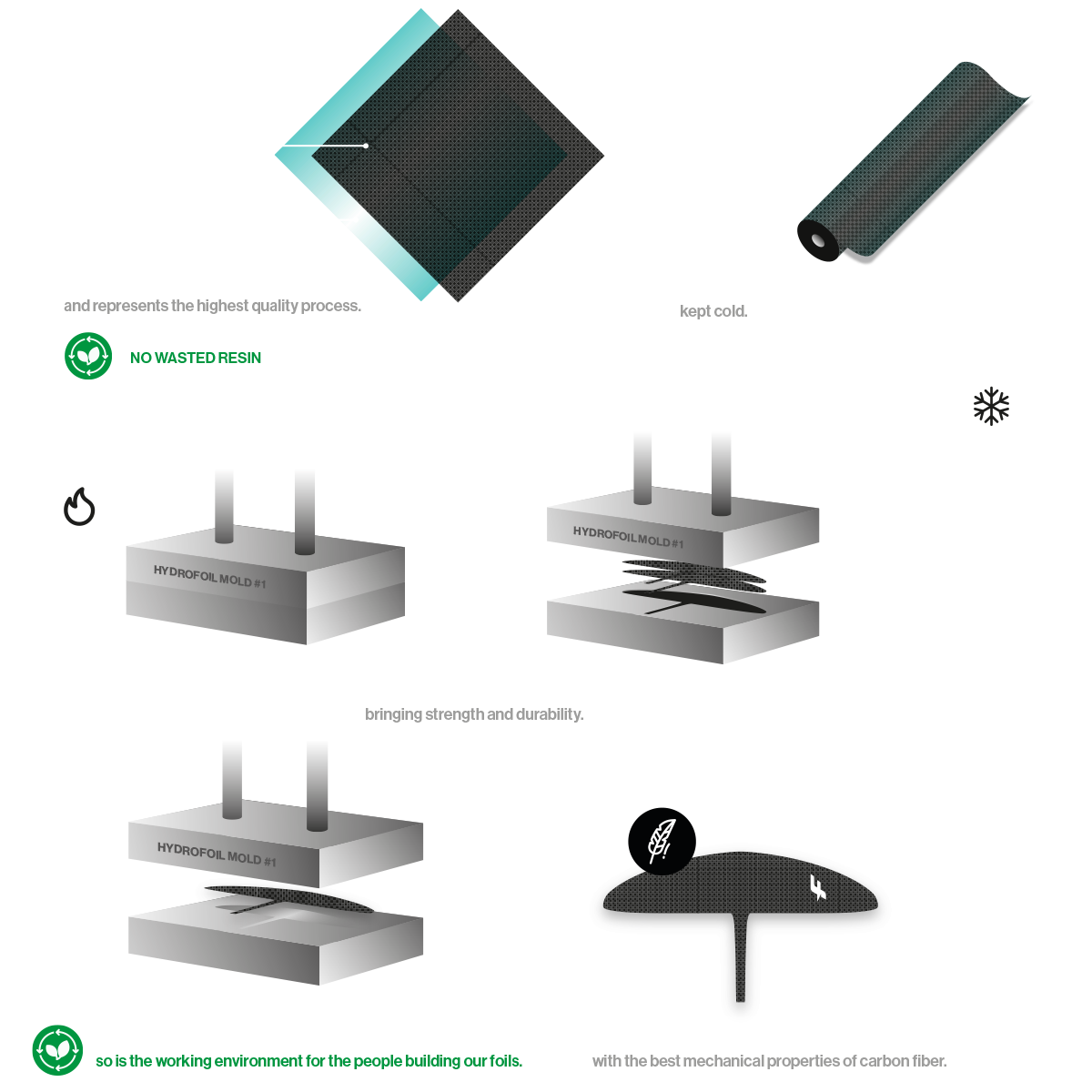

PRE PREG TECHNOLOGY

Pre-preg makes the foils stiffer and stronger. With pre-preg fabrics, the carbon fiber is directly impregnated with epoxy resin by its manufacturer. This guarantees a perfect ratio between epoxy and carbon and represents the highest quality process. It is then cured at high temperature, bringing strength and durability.

Quality control is much better and so is the working environment for the people building our foils. Pre-preg fabrics offer the lightest weight with the best mechanical properties of carbon fiber.

Technical Specifications

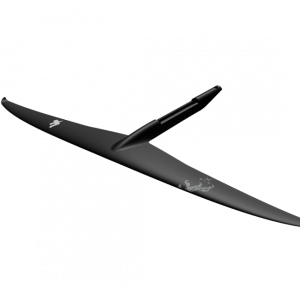

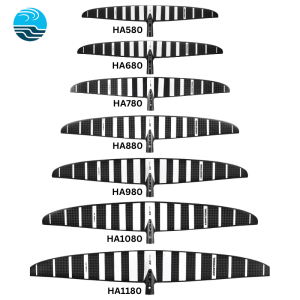

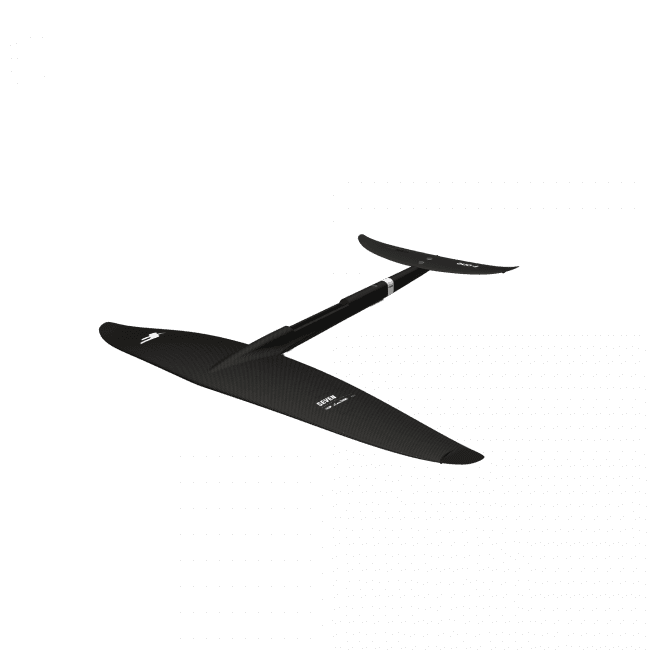

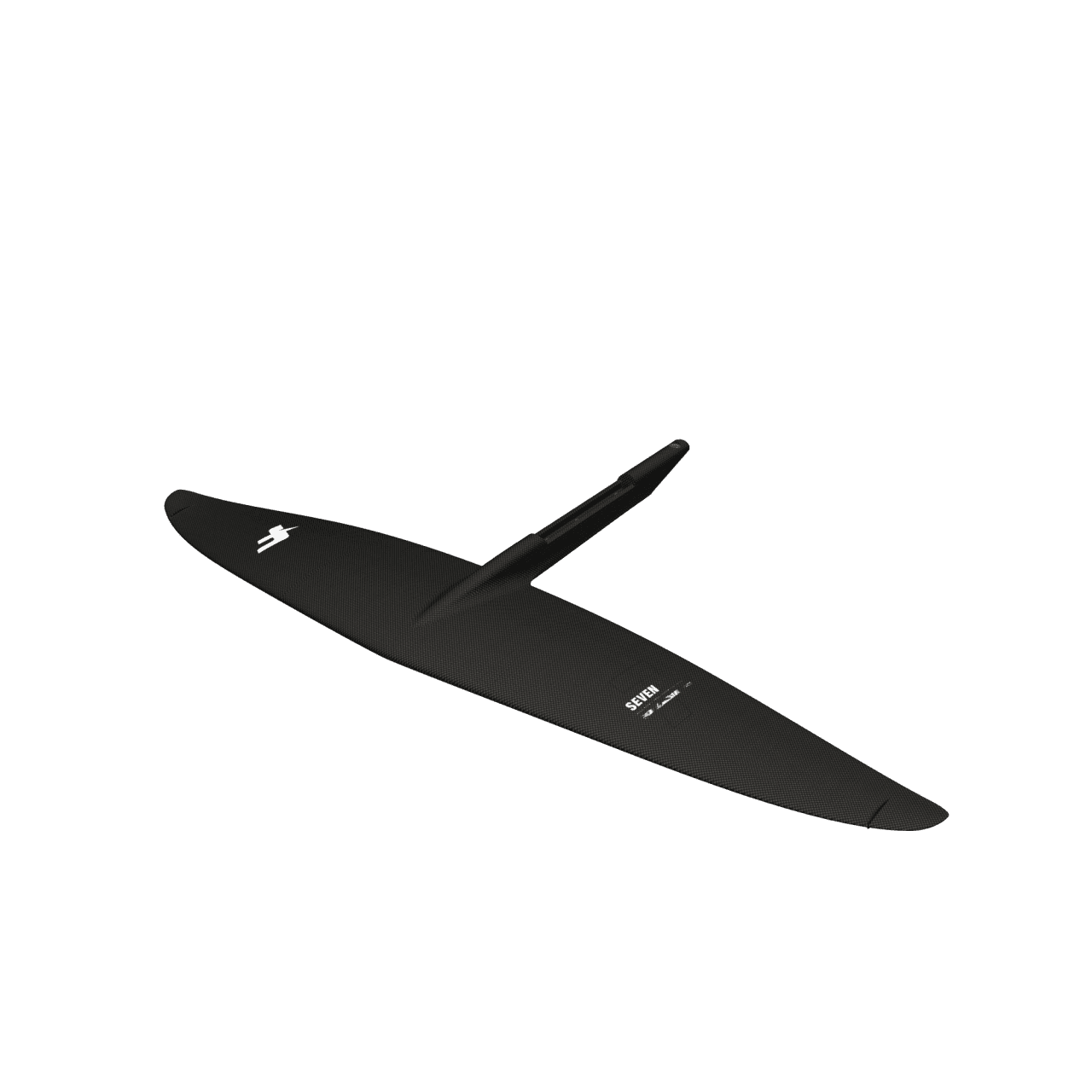

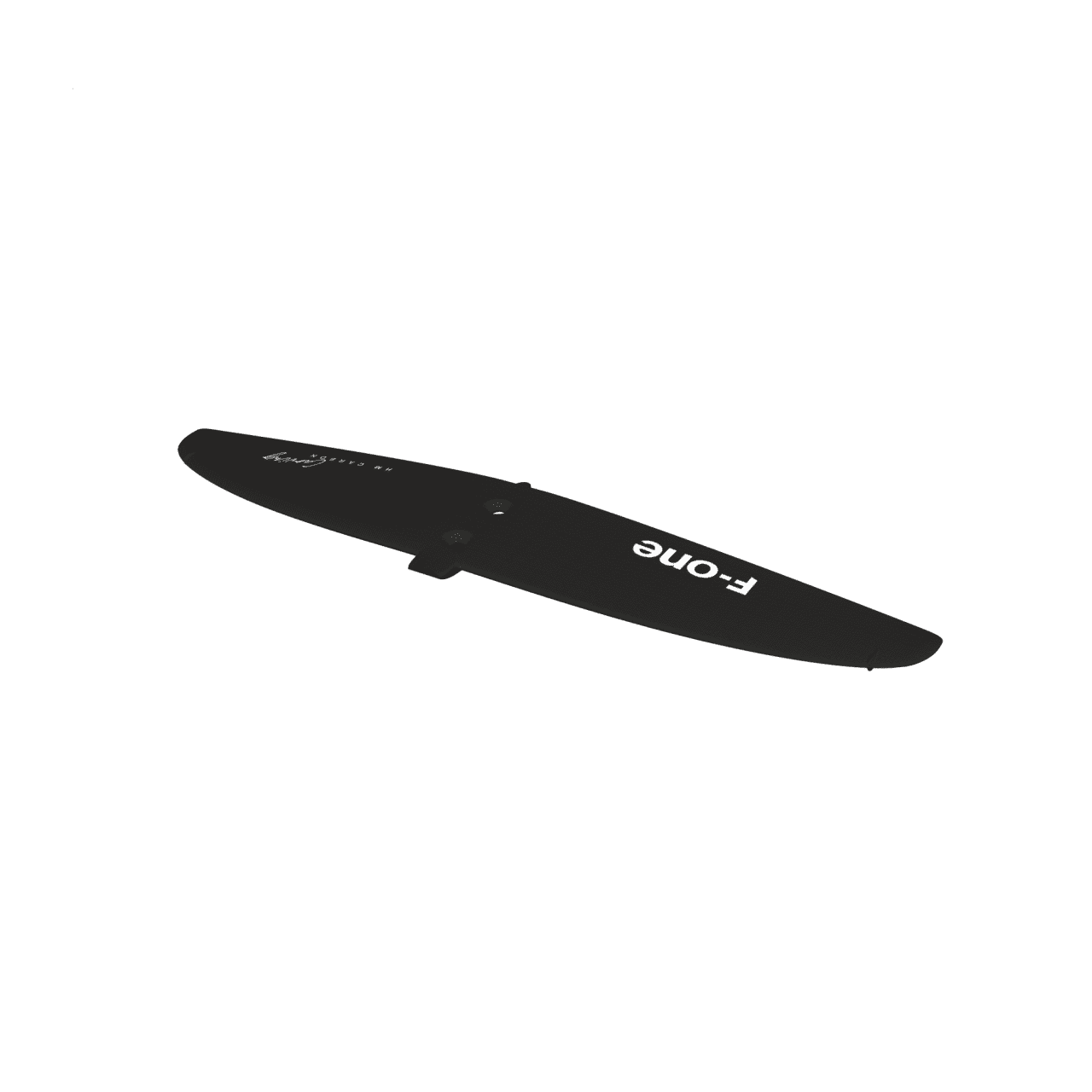

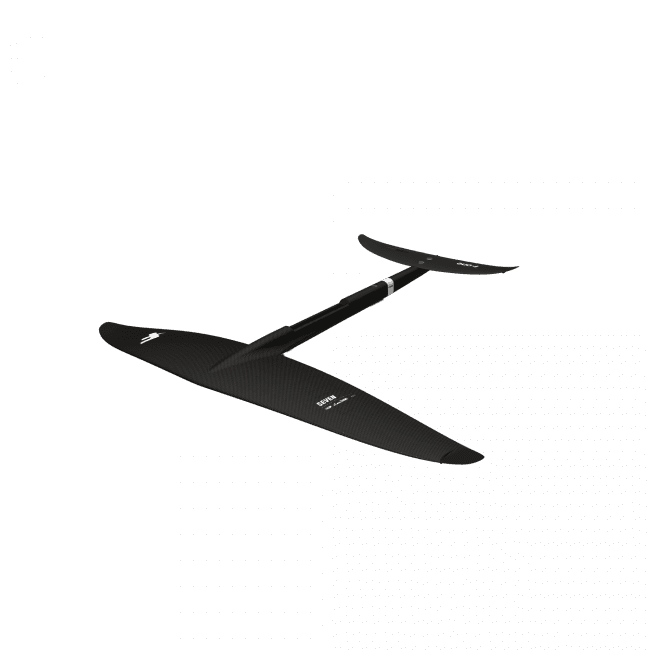

The SEVEN SEAS’s high aspect ratio and thin profile brings great downwind abilities and offers the best glide. The front wing is equipped with fences on the wingtips to reduce the induced drag and improve the foil’s overall performances and maneuverability.

Once you’re up to your cruising speed, its lift will make it easy for you to keep your glide for a long time. Pumping is reliable and constant even at low speeds, and you will be able to connect the waves and catch any upcoming bumps more easily.

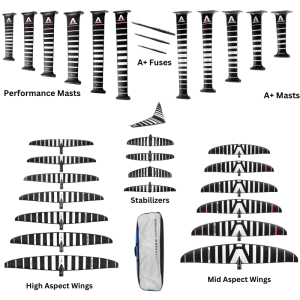

This new line positions itself perfectly as an intermediary between the EAGLE HM CARBON and the PHANTOM CARBON ranges. Built using the Monobloc structure with pre-preg carbon, the foils are both very light and strong.

This setup brings improved load transmission and better stiffness throughout the different parts for maximum control. The TITAN connection allows to plug in either an aluminum or carbon mast, and the fuselage is split in two to facilitate transport.

Technical Specifications

The SEVEN SEAS’s high aspect ratio and thin profile brings great downwind abilities and offers the best glide. The front wing is equipped with fences on the wingtips to reduce the induced drag and improve the foil’s overall performances and maneuverability.

Once you’re up to your cruising speed, its lift will make it easy for you to keep your glide for a long time. Pumping is reliable and constant even at low speeds, and you will be able to connect the waves and catch any upcoming bumps more easily.

This new line positions itself perfectly as an intermediary between the EAGLE HM CARBON and the PHANTOM CARBON ranges. Built using the Monobloc structure with pre-preg carbon, the foils are both very light and strong.

This setup brings improved load transmission and better stiffness throughout the different parts for maximum control. The TITAN connection allows to plug in either an aluminum or carbon mast, and the fuselage is split in two to facilitate transport.